Solar Energy Powered Net-House with Root Zone Cooling Hydroponic System

Abstract

Control environment agriculture (CEA) is a key pillar of desert farming in desert farming. The main technical problem of conventional greenhouses is maintaining the inside air temperatures and relative humidity favourable for plant growth under desert farming system. The evaporative cooling system is widely used in the desert ecosystems with low efficiency due to the extreme temperature and relative humidity in the coastal areas. Moreover, the evaporative cooling system requires large amounts of water and grid energy which is not available in the desert ecosystems.

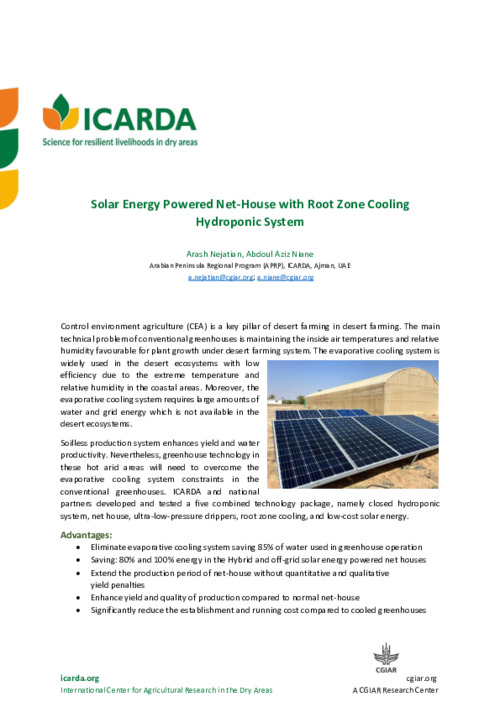

Soilless production system enhances yield and water productivity. Nevertheless, greenhouse technology in these hot arid areas will need to overcome the evaporative cooling system constraints in the conventional greenhouses. ICARDA and national partners developed and tested a five combined technology package, namely closed hydroponic system, net house, ultra-low-pressure drippers, root zone cooling, and low-cost solar energy.

Advantages:

•	Eliminate evaporative cooling system saving 85% of water used in greenhouse operation

•	Saving: 80% and 100% energy in the Hybrid and off-grid solar energy powered net houses

•	Extend the production period of net-house without quantitative and qualitative yield penalties

•	Enhance yield and quality of production compared to normal net-house

•	Significantly reduce the establishment and running cost compared to cooled greenhouses

Two options of low-cost solar energy technologies, namely AC/DC hybrid and 100% off-grid are available in the market now (figure1 and Figure2). Utilizing solar energy reduces the running cost and CO2 emissions into the atmosphere.

In UAE, a study on cucumber production under net-house with solar energy powered RZC resulted in:

•	Extending cucumber production until mid-June without quantitative and qualitative yield penalties

•	Water productivity per crop reached 37kg/m3 compared to 8 kg/m3 in a cooled greenhouse

•	14% increase in net return and a 28% reduction in the cost of production

•	Saving 6650-kWh electricity, equivalent to 4.7 metric tons of Co2 sequestration